Introducing Slip Sheets

At Gerex America, we specialize in providing top-of-the-line transportation stability solutions. One of our flagship offerings is the OCTOPUS® ANTI-SLIP PAPER SOLUTION, which plays a pivotal role in enhancing the safety and efficiency of goods during handling and transportation. Slip Sheets are an integral component of our strategy to optimize the loading of trucks and containers, ensuring goods are secured throughout their journey.

Slip Sheets serve as a lightweight and cost-effective alternative to traditional wooden or plastic pallets. Their primary function is to provide a stable base for stacking goods, which can be instrumental in maximizing space utilization within containers and trucks. The adoption of Slip Sheets can result in a significant reduction in shipping and packaging costs while maintaining the integrity of transported goods.

Benefits of Using Slip Sheets

The Advantages of Slip Sheets in Material Handling

The slim profile of Slip Sheets allows for more products to be stored and shipped within the same space, compared to bulkier pallet solutions. This efficient use of space directly correlates to cost savings on shipping and materials. Additionally, the compatibility of Slip Sheets with automated handling systems streamlines the loading and unloading process, reducing labor costs and enhancing operational efficiency.

Cost Reduction and Environmental Impact

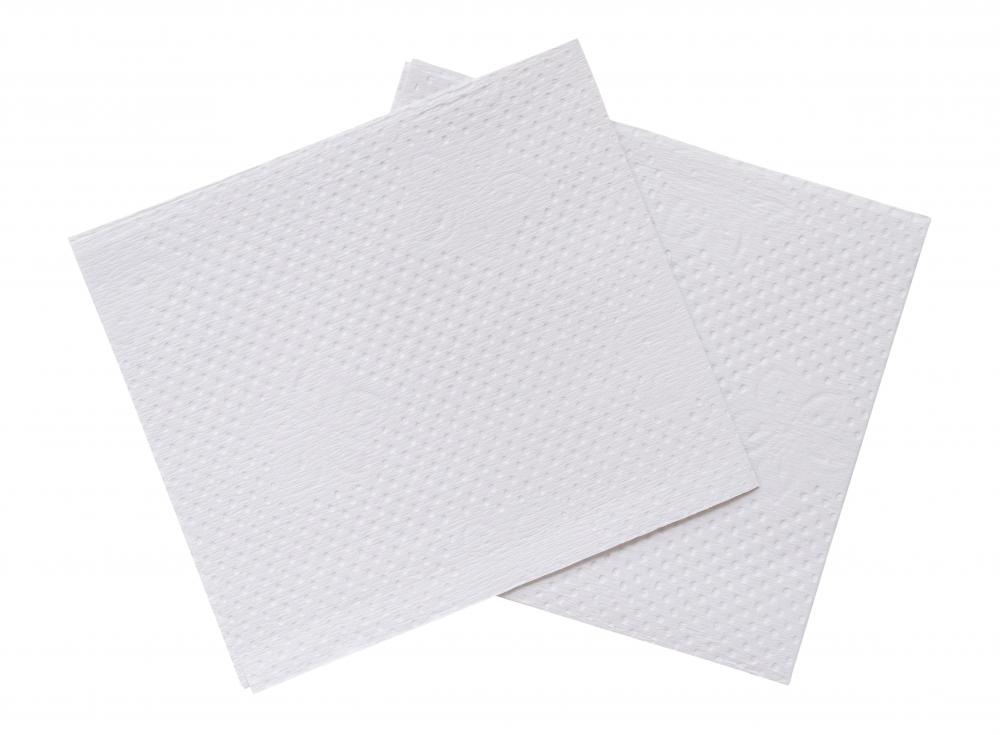

Our OCTOPUS® ANTI-SLIP PAPER SOLUTION is designed not only to improve load stability but also to minimize the need for tertiary packaging materials. This reduction in material usage not only leads to cost savings but also contributes to our clients’ sustainability goals by lessening waste and environmental impact.

Optimizing Your Supply Chain with Slip Sheets

Choosing the right Slip Sheets for your operation involves understanding the specific needs of your supply chain. Gerex America offers a variety of anti-slip paper products tailored to different weight categories and types of goods. Our expert team can advise on the optimal solution to ensure maximum stability and efficiency, whether for light products requiring manual application or heavy items suited to automatic systems.

Implementing Slip Sheets into your logistics processes can transform how you approach material handling and transportation. By optimizing the loading of trucks and containers, businesses can achieve significant cost savings while improving the safety and integrity of their goods in transit.

Our Range of Anti-Slip Products

- 65G ANTI-SLIP OCTOPUS PAPER®, ideal for light products with manual application.

- 100G ANTI-SLIP OCTOPUS PAPER®, also suitable for light products requiring manual handling.

- 150G ANTI-SLIP OCTOPUS PAPER®, designed for medium to heavy products, compatible with manual or automatic application.

- 220G ANTI-SLIP OCTOPUS PAPER®, for heavy products, available for both application methods.

- 270G ANTI-SLIP OCTOPUS PAPER®, aimed at heavy to extra-heavy products, with application flexibility.

- 450G ANTI-SLIP OCTOPUS PAPER®, the heavier option for extra-heavy products, suitable for varied application methods.

- 550G ANTI-SLIP STABILIZATOR, our heaviest solution, perfect for use under pallets and adaptable to manual or automatic application.

Client Success Stories

Our dedication to enhancing supply chain efficiency spans across various industries. By integrating our OCTOPUS® ANTI-SLIP PAPER SOLUTION, businesses have realized substantial improvements in load stability and cost savings. From reducing the occurrence of damaged goods to optimizing container space, our clients’ success stories underscore the transformative impact of adopting Slip Sheets in their logistics operations.

One memorable instance involved a client who was facing challenges with securing their goods during long-haul transportation. By switching to our anti-slip paper solution, they were able to not only improve the stability of their loads but also significantly reduce their environmental footprint by eliminating the need for plastic stretch wrap and other stabilizing materials.

Choosing the Right Slip Sheet for Your Needs

Selecting the appropriate Slip Sheets involves considering the weight and dimensions of your goods, as well as the specific requirements of your supply chain. Our team at Gerex America is equipped with the expertise to guide you through the selection process, ensuring you adopt the most effective and cost-efficient solution for your operation.

Our thorough understanding of logistics challenges and our innovative approach to solutions make us a preferred partner for businesses looking to enhance their material handling processes. By leveraging Slip Sheets and our comprehensive range of anti-slip paper products, companies can achieve improved load stability, reduced packaging costs, and a more sustainable supply chain.

Contact Us for More Information

If you’re looking to transform your transportation and material handling strategies, Gerex America is here to help. Reach out to us to learn more about how our OCTOPUS® ANTI-SLIP PAPER SOLUTION can benefit your operation. Our team is ready to provide personalized advice and solutions tailored to meet your unique requirements.

Embrace the change towards more efficient, cost-effective, and stable transportation solutions with Gerex America. Let us be the driving force behind your supply chain optimization efforts. Contact us today to begin your journey towards greater operational excellence.

What are slip sheets used for?

Slip sheets are essentially thin pallet-sized sheets made of heavy-duty paper, plastic, or a combination of both, designed to replace traditional wooden or plastic pallets in the transportation and storage of goods. Their primary use? To act as a stable base for stowing goods securely during transit. Imagine you’re trying to pack a box securely for a move; slip sheets serve a similar purpose but on a much larger scale, enhancing loading efficiency and ensuring products reach their destination safely. They’re particularly beneficial in maximizing space within containers and trucks, allowing more products to be transported at once, which in turn, can lead to significant cost savings.

What is the difference between a pallet and a slip sheet?

While both serve the purpose of stabilizing goods for transport and storage, the primary difference lies in their structure and material. Pallets are rigid platforms made from wood, metal, or plastic and are designed to be moved with a forklift or pallet jack. Slip sheets, on the other hand, are flat, thin sheets that can be made of reinforced paper or plastic. They require a specialized attachment on a forklift called a push-pull device to be moved. The key advantage of slip sheets is their lightweight and space-saving design, allowing more goods to be packed into a single shipment and reducing the need and cost associated with pallet use.

What is the difference between a tie sheet and a slip sheet?

The primary difference between tie sheets and slip sheets lies in their usage within the packing and transportation process. Slip sheets are used to replace pallets entirely, offering a stable base for goods during transport. Tie sheets, however, are used in conjunction with pallets or slip sheets, placed between layers of products to stabilize and secure the load further. They help distribute the weight evenly and prevent shifting or damage during movement. Essentially, while slip sheets serve as an alternative to pallets, tie sheets enhance the stability of goods, whether they’re stacked on pallets or slip sheets.

What are the disadvantages of slip sheets?

Although slip sheets offer numerous benefits, including cost and space savings, they are not without their downsides. For one, the use of slip sheets requires specialized equipment, such as forklifts with push-pull attachments, which can be an additional expense for warehouses not already equipped. Additionally, slip sheets may not provide as much structural support as wooden or plastic pallets, making them unsuitable for certain types of heavy or bulky goods. There’s also a learning curve involved in handling them efficiently, meaning staff might need training to avoid potential delays or damage to goods during loading and unloading processes.

How to choose the right slip sheet for your needs?

Selecting the right slip sheet involves considering several key factors, such as the weight and type of goods you’re transporting, as well as the handling methods you’ll be using. At Gerex America, we offer a range of slip sheets varying in thickness and strength, tailored to different needs. It starts with understanding your product’s weight distribution and how it’ll interact with the slip sheet during transit. For lighter goods, a thinner slip sheet might suffice, while heavier items will require a thicker, more durable sheet. Consulting with our experts can help you navigate these choices, ensuring that you select the most efficient and cost-effective solution for your specific logistics challenges.

How do slip sheets contribute to environmental sustainability?

Slip sheets stand out not only for their efficiency and cost-effectiveness but also for their positive environmental impact. By opting for slip sheets over traditional wooden or plastic pallets, companies can significantly reduce their reliance on natural resources. These thin sheets are often made from recycled materials and are themselves fully recyclable, contributing to a circular economy. Additionally, their lighter weight leads to lower fuel consumption during transportation, further reducing the carbon footprint of shipping processes. Embracing slip sheets is a step towards sustainable practices, aligning operational efficiency with environmental responsibility. Have you considered how your company’s shipping methods could be more eco-friendly?

Additional Resources

- Environmental Protection Agency (EPA) – Transportation and Air Pollution: Learn more about the impacts of transportation on air quality and climate change.

- National Renewable Energy Laboratory (NREL) – Transportation Research: Access research and resources on sustainable transportation solutions.

- U.S. Department of Transportation: Explore information on transportation policies, safety, and infrastructure in the United States.

Recent Comments